Explanation of technical information

To ensure that you select wheels compatible with your vehicle and avoid any

unpleasant surprises

it is important to understand their technical

specifications. Take a moment to familiarize yourself with these specifications

and begin shopping for your new wheels with peace of mind.

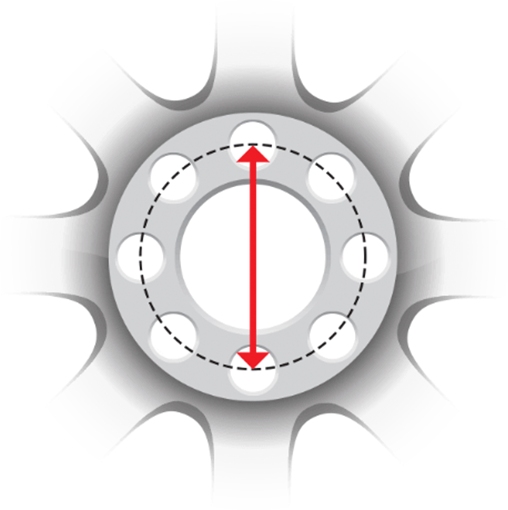

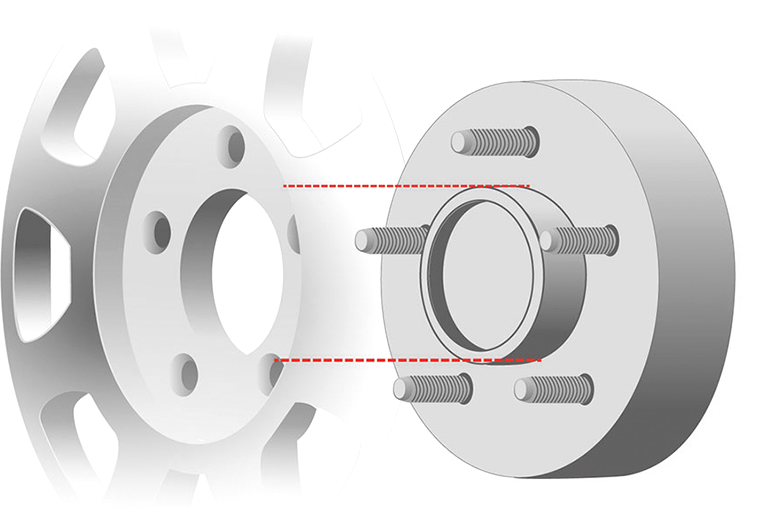

BOLT PATTERN

The bolt pattern is calculated using the number

of holes on the wheel and an imaginary circle passing through the center of the

wheel studs, representing its diameter in millimeters (mm). In the case of a

wheel with five (5) holes and a circle diameter of 114.3 mm, the bolt pattern

of this wheel is therefore 5x114.3. It is important to ensure that the bolt

pattern of your vehicle matches that of your wheels; otherwise, it will be impossible

to install your wheels.

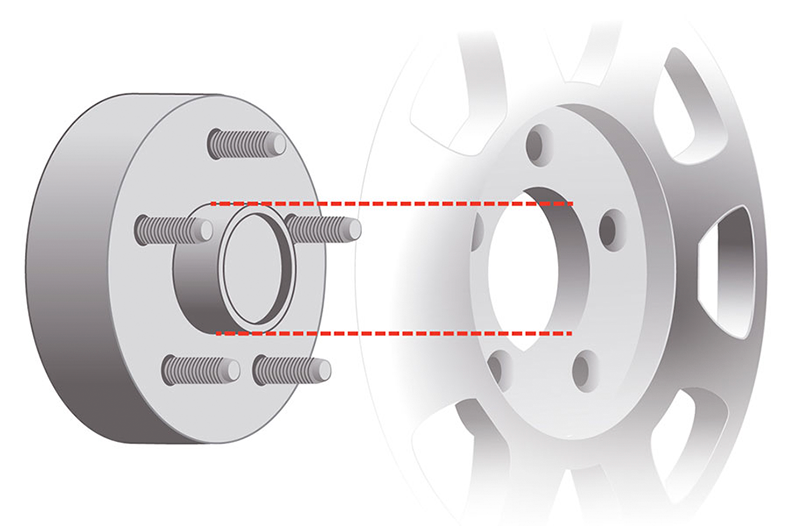

CENTRE BORE

The center bore is the central hole located in

the middle of your wheels. This allows for proper positioning of the wheel on

the vehicle's hub. It is important that the wheel's center bore diameter is

equal to or larger than the hub size of the vehicle. The center bore is

measured in millimeters (mm) using the diameter of this hole.

LUG CENTRIC

This type of centering is very common for steel

wheels but uncommon for alloy wheels. The principle is the same as hub

centering, except that this type of centering is done using the lug nuts. The

reason for this type of centering lies in the fact that it is impossible to use

centering rings with steel wheels.

HUB CENTRIC

Hub centering is done using the central hole

located in the middle of the wheel. Once installed on the vehicle's hub, this

helps prevent possible vibrations. Most aftermarket wheels require the use of

centering rings, as they are designed with a larger hub to fit a greater number

of vehicles. These centering rings have an outer diameter corresponding to the

size of the wheel's hub diameter and an inner diameter corresponding to the

size of the vehicle's hub, ensuring a perfect fit no matter the vehicle on which

you install the wheels.